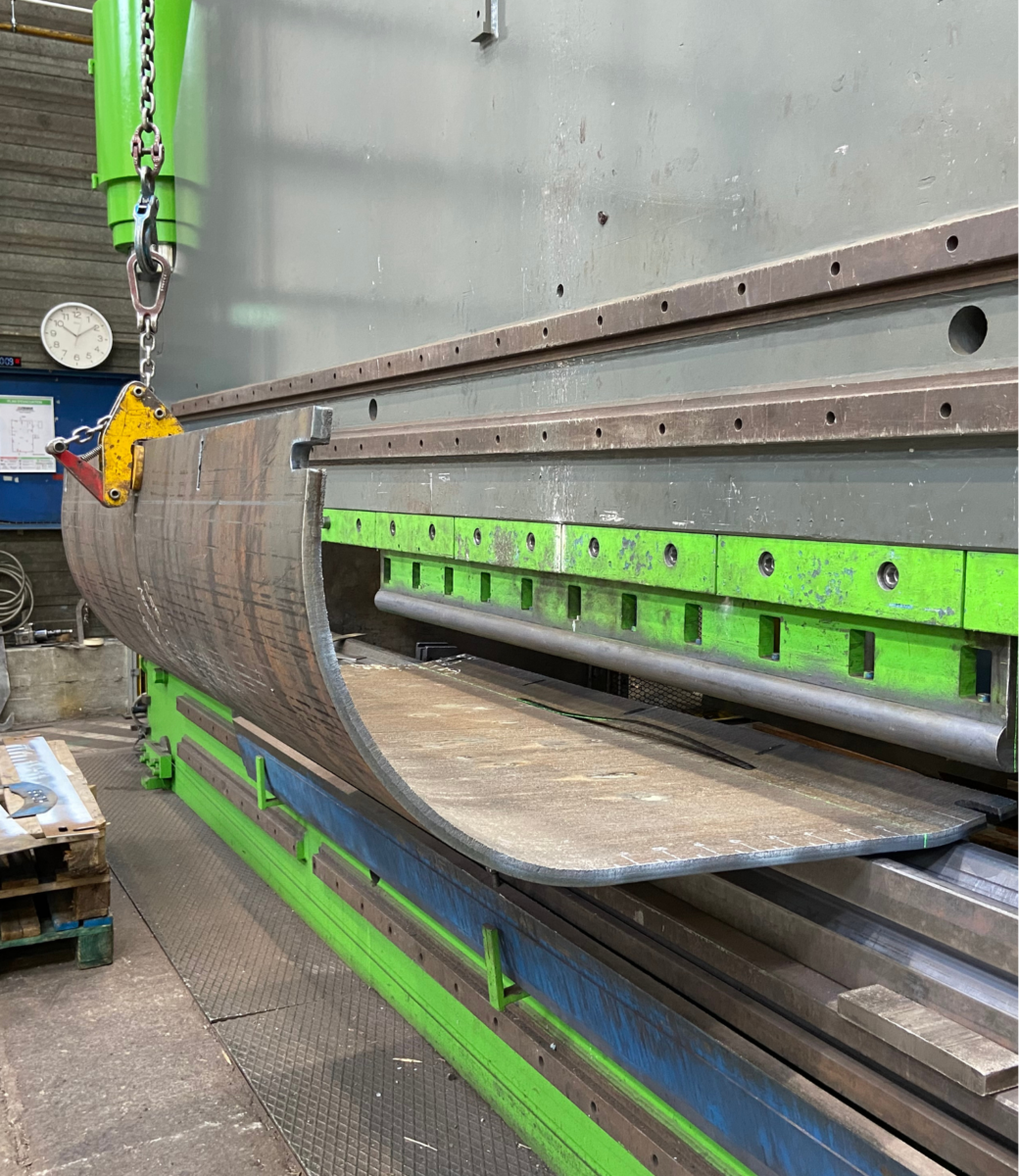

Creusabro abrasion-resistant steel

Extraction, transportation, and handling of bulk products form the foundation of mining industries. Hard rocks and violent impacts often lead to significant wear issues. Creusabro® extends the lifespan of critical components and prevents costly machine downtime.

Creusabro®: In-service hardening, up to +70 HB

Creusabro®: High-temperature resistance: 450°C.

The Creusabro® range is based on an innovative manufacturing process and metallurgy, setting it apart from traditional low-carbon steels.

These wear-resistant steels are designed to provide an optimal balance between wear resistance, ease of implementation, and resilience.

Their resistance is enhanced through a surface hardening effect of +70 HB, resulting from local plastic deformations caused by impact with rocks or the pressure from abrasive particles. This reaction is known as the TRIP effect (Transformation Induced by Plasticity).

In mobile equipment, payload and weight are also significant concerns. Creusabro® requires thinner thicknesses for the same service life compared to conventional wear-resistant steels, thereby allowing for substantial weight savings and increased payload potential.

Creusabro 4800

Advanced wear technology.

Creusabro® 4800 stands out as an exceptionally abrasion-resistant steel, offering wear resistance surpassing conventional water-quenched 400 HB steels by 40 to 50%.

Beyond its remarkable hardness, the mechanical properties of Creusabro result from metallurgy enriched with chrome, nickel, and molybdenum, along with a specific heat treatment.

| Hardness (HB) | Mechanical Characteristics | Resilience |

|---|---|---|

| 370 (as delivered) 440 (after work-hardening) Guarantee: 350-420 |

Re (MPa) : 900 Rm (MPa) : 1200 A (%) 12 |

50 J at -40°C Thickness: 30 to 120 mm 36 J at -20°C Thickness: >30 mm |

Typical value at delivery.

Main Applications: Wear parts, bucket liners, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, etc

Creusabro 4800® Technical Datasheet

Creusabro 6400

Combining performance and processability.

The latest addition to the Creusabro range, Creusabro 6400, is designed to meet the needs of builders and users seeking an abrasion-resistant steel that is more performance-oriented than conventional 450 HB steels, yet easier to work with than a 500 HB steel.

| Hardness (HB) | Mechanical Characteristics | Resilience |

|---|---|---|

| 460 (as delivered) 530 (after work-hardening) Guarantee: 425-490 |

Re (MPa) : 1000 Rm (MPa) : 1400 A (%) 12 |

40 J at -40°C

Guarantee: 36 J at -20°C (thickness <30mm) |

Typical value at delivery.

Main Applications : Wear parts, bucket liners, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, etc.

Creusabro 6400® Technical Datasheet

Creusabro 8000

A high-performance steel resistant to wear and impact.

Creusabro® 8000 is an oil-quenched wear-resistant steel.

It is characterized by its exceptional resistance to abrasion, providing increased durability 40 to 50% higher than conventional water-quenched 500 HB steels.

| Hardness (HB) | Mechanical Characteristics | Resilience |

|---|---|---|

| 470 (livraison) 540 (après d’écrouissage) Garantie : 430-500 |

Re (MPa) : 1250 Rm (MPa) : 1630 A (%) 12 |

50 J à -20°C ép. 20 à 100 mm Garantie : 27 J à -20°C ép. 20 à 100mm |

Typical value at delivery.

Main Applications: Wear parts, bucket liners, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, etc.

Creusabro 8000® Technical Datasheet

Explore our DURSTEEL® Range, the standard abrasion-resistant steel developed by the wear solutions specialist for the past 50 years!

Latest news

Dive into the latest news from Produr, where we highlight exciting case studies on products from the mineral processing sector, concrete examples of equipment upgrades, and the very latest advances in manufacturing and product reliability.

Read our news