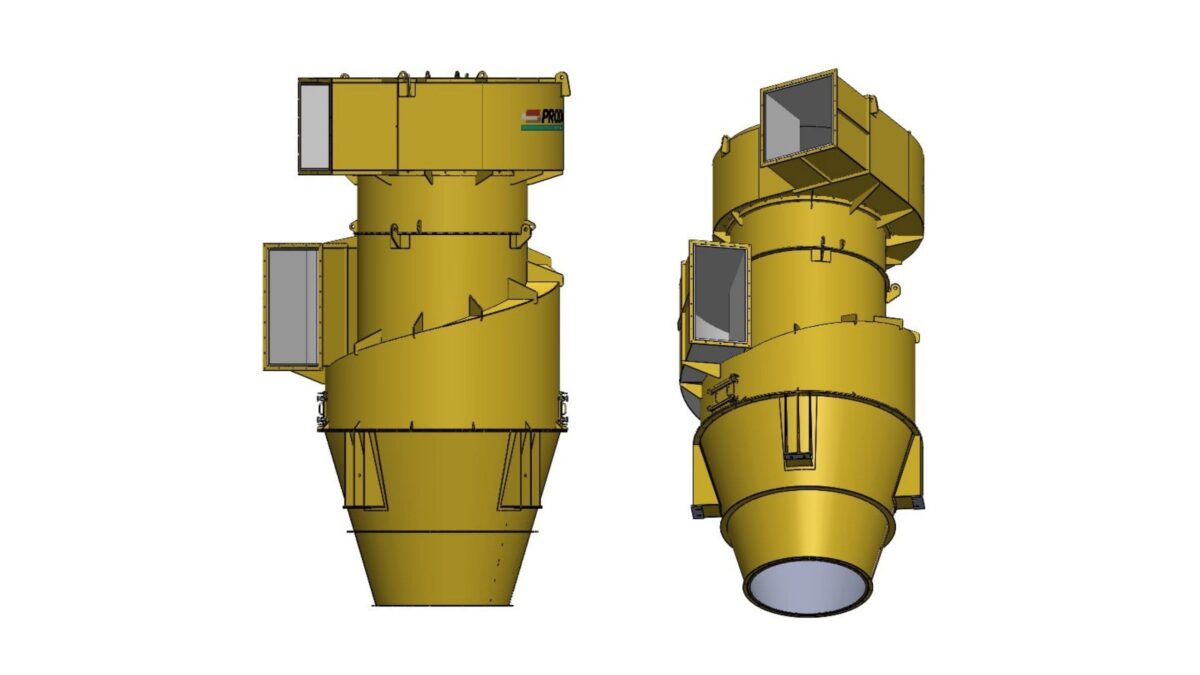

Wear-resistant cyclones

Explore Produr’s wear-resistant materials for cyclones to optimize the overall lifespan of the device.

References: Eramet, Glencore, Iamgold, Barrick Gold, AngloGold, First Quantum Minerals.

The lifespan of our cyclones is 3 to 5 times longer than a cyclone with wear-resistant polymer lining

Our expertise

Produr offers you a wide range of resistant materials specially designed for your cyclones.

From dimensioned plans or on-site surveys conducted by us, we redesign and manufacture new cyclones lined with ceramics.

We can modify their internal geometry to ensure a smoother movement of the pulp and reduce wear, while maintaining the flow rates and input and output speeds.

The solutions take into account your needs, types of wear, and the specificities of your equipment :

- Characteristics of your equipment remain unchanged.

- Measurement taking includes positioning and dimensioning of supports.

- Assembly is carried out in situ, replacing existing boxes through the use of adaptation flanges.”

Wear-resistant materials for cyclones

The use of advanced technical ceramics tailored to each zone of the cyclone allows for optimizing the overall lifespan of the device.

Ceramic Aldur 240 is used for the head and upper parts of the cone.

Ceramic Durhart 200 is used for the lower parts of the cone.

Our recharged sheet Duraplate can be used in certain cases for the cyclone’s chimney.

The parts are monolithic; therefore, there is no risk of delamination of the coating, which is securely held within its metal envelope by a specific mortar.

The lifespan of our cyclones is 3 to 5 times longer than a cyclone coated with wear-resistant polymer.

Latest news

Dive into the latest news from Produr, where we highlight exciting case studies on products from the mineral processing sector, concrete examples of equipment upgrades, and the very latest advances in manufacturing and product reliability.

Read our news