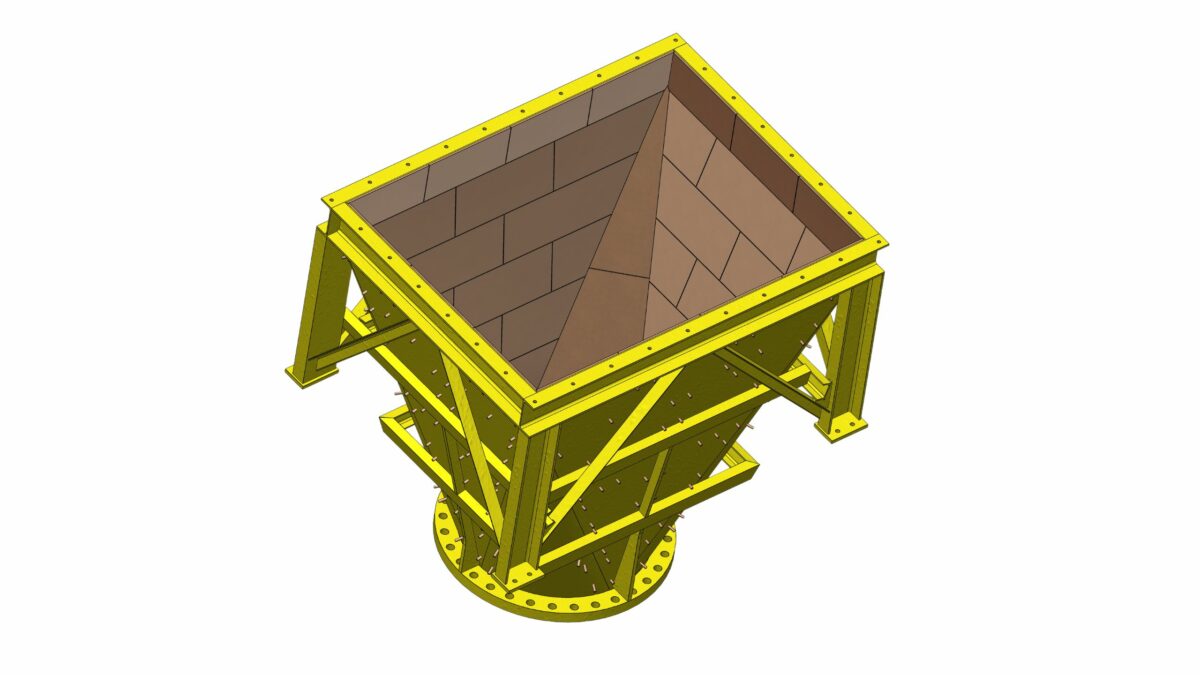

Liners for hoppers, chutes, conveyors

Advice, recommendations, and anti-wear solutions to increase the service life of your hoppers, chutes, and conveyor.

References : Eramet, Glencore, Iamgold, Barrick Gold, Anglogold, First Quantum Minerals

Creusabro 8000 extends the lifespan by at least 50% compared to a standard 450HB anti-abrasion steel.

Our expertise

Starting from existing dimensions and specific constraints in your installations, Produr integrates tailored coatings to address specific wear and material issues. Thus, impact, sliding, and clogging zones can benefit from differentiated solutions within the same hopper.

To ensure easy equipment maintenance, Produr offers modular lining solutions.

Our materials allow the potential realization of all types of hoppers or silos.

We handle layout studies, deliver labeled parts to facilitate assembly, and ensure careful management of the interface between the protective elements and the existing structure, thus guaranteeing the optimal efficiency of your liners and their quick replacement.

Blades for hoppers, chutes, conveyors

For Wear Phenomena:

Anti-Abrasion Steel (Dursteel® and Creusabro®): Designed for moderate to high wear, these steels ensure superior resistance and exceptional durability.

Clogging combined with wear

HiSPEED® Cladding Plate: A specialized solution to counter clogging and ensure consistent performance even in high-flow conditions.

Technical Ceramics (Aldur® 240, Durhart® 200, Durzalt® 40): Ideal for resisting light to moderate wear, these ceramics provide robust protection in demanding conditions.

Our Creusabro 8000 liners have a lifespan twice as long as traditional 450HB steel liners.

Latest news

Dive into the latest news from Produr, where we highlight exciting case studies on products from the mineral processing sector, concrete examples of equipment upgrades, and the very latest advances in manufacturing and product reliability.

Read our news